Updates

01

September

-

Solidified design challenge and novel idea

-

Conducted intense literature review

-

Established communications with potential manufacturers and industry-related professionals

02

October

-

Cataloged substantial ideas presented in experiments and realistic applications

-

Drafted practical automated control systems for regulating pressure differences

-

Selected LO2 as the preferred propellant for expansion and transfer

03

November

-

Began outlining apparatus designs

-

Calculated Fluid and Thermal responses present within the proposed system

-

Replaced LO2 with LN2 for practical purposes in testing

-

Combined theoretical design philosophies with accurate experimental testing

-

Developed differential pressure system control schemes

04

December

-

Presented SP1 final presentation to the Mechanical Engineering Department

-

Simulated Thermal effects on apparatus' safety

-

Computed Fluid behavior in lunar and cis-lunar settings

-

Finalized components for the budget

05

January

-

Finalized purchasing for components

-

Drafted a full vacuum chamber model for apparatus housing

-

Started work on pressure-differential dependent controlling mechanism for solenoid application

-

Began utilization of remote computing for extended duration of fluid simulation

06

February

-

Presented SP2 progress presentation to the Mechanical Engineering Class of 2025

-

Full Apparatus modeled

-

Completed component order requests

-

Organized testing area and safety precautions for expected April experiments

07

March

-

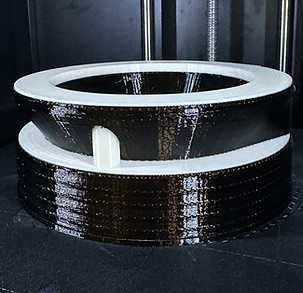

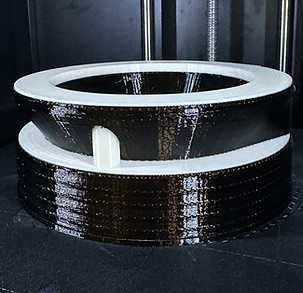

Began manufacturing of garelite panels for the vacuum chamber walls

-

Organized components and updated existing models to reflect sizing changes

08

April

-

Selected as Finalists for the 2025 HuLC Competition

-

Finished garelite enclosure for vacuum chamber

-

Begun testing various cryogenic rated components

09

May

-

Presented Project to Mechanical Engineering Departments for Senior Design 2

-

Presented project for COSA poster Keynote presentations

10

June

-

Competed against 11 other schools at the HuLC Forum

-

Toured several Nasa fascilities in the Huntsville area

-

Finalized presentation package for forum

2024-2025 Timeline

01

September

-

Solidified design challenge and novel idea

-

Conducted intense literature review

-

Established communications with potential manufacturers and industry-related professionals

02

October

-

Cataloged substantial ideas presented in experiments and realistic applications

-

Drafted practical automated control systems for regulating pressure differences

-

Selected LO2 as the preferred propellant for expansion and transfer

03

November

-

Began outlining apparatus designs

-

Calculated Fluid and Thermal responses present within the proposed system

-

Replaced LO2 with LN2 for practical purposes in testing

-

Combined theoretical design philosophies with accurate experimental testing

-

Developed differential pressure system control schemes

04

December

-

Presented SP1 final presentation to the Mechanical Engineering Department

-

Simulated Thermal effects on apparatus' safety

-

Computed Fluid behavior in lunar and cis-lunar settings

-

Finalized components for the budget

05

January

-

Finalized purchasing for components

-

Drafted a full vacuum chamber model for apparatus housing

-

Started work on pressure-differential dependent controlling mechanism for solenoid application

-

Began utilization of remote computing for extended duration of fluid simulation

06

February

-

Presented SP2 progress presentation to the Mechanical Engineering Class of 2025

-

Full Apparatus modeled

-

Completed component order requests

-

Organized testing area and safety precautions for expected April experiments

07

March

-

Began manufacturing of garelite panels for the vacuum chamber walls

-

Organized components and updated existing models to reflect sizing changes

08

April

-

Selected as Finalists for the 2025 HuLC Competition

-

Finished garelite enclosure for vacuum chamber

-

Begun testing various cryogenic rated components

09

May

-

Presented Project to Mechanical Engineering Departments for Senior Design 2

-

Presented project for COSA poster Keynote presentations

10

June

-

Competed against 11 other schools at the HuLC Forum

-

Toured several Nasa fascilities in the Huntsville area

-

Finalized presentation package for forum